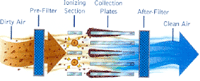

E.P. units or Electrostatic air cleaner’s work on the principle of attraction and repulsion of  electrical charges known as electrostatic precipitation. E.P. units can be used within various particulate and fume extract systems and can remove particles down to 0.01 microns in size.

electrical charges known as electrostatic precipitation. E.P. units can be used within various particulate and fume extract systems and can remove particles down to 0.01 microns in size.

A wide duty range is available from 1000 m³/hr upwards.

The air cleaners are housed within a fabricated mild steel cabinet with an epoxy powder coated finish and incorporate three-stage filtration.

1st Stage

1st Stage

The mechanical primary filter, usually an aluminium ribbon panel filter, is used to remove the larger particles of contaminant. This panel filter is removable and washable.

2nd Stage

The secondary filter or collecting cell incorporates an ionising section with stainless steel blades that positively charge the airborne particulate. The contaminated airstream then enters the collecting section, which features a series of earthed laminar collecting plates, which attract the charged particulate. The collecting cells are removable and washable.

3rd Stage

The third filter section features either a removable vee pleat filter panel or carbon filter, dependent upon the process application. The carbon filter can remove trace odours and fumes prior to discharging the cleaned air back into the workshop.

E.P. units have been employed on various applications including;

.Mist and fume from grinding and metal cutting

.Welding, soldering and brazing of metals

.Smoke and fumes from plastic and rubber extrusion

.Oil mist from temper furnaces, oil quench baths and automatic food frying machines

.Fumes and odours from plastic cutting and forming

Please note that E.P. units require regular washing of collection surfaces to maintain operating efficiency. E.P. units have been in operation for many years and are a recognised method of removing airborne contaminant and odours from various applications whilst maintaining exposure levels below OEL’S set under current C.O.S.H.H. and EH40 regulations.